Algae is in Fashion: (2) Alginate Fibers are Dope

Episode #04: The stylish biotech that could literally make our world cooler (Part 2)

In the last issue of The Blob, we took a look at the algal derived dyes and pigments for the fashion industry. We’ll save pigments for beauty, food (and paint!) for another time. Dyes are just one of many applications that could impact several different high value markets. Only in Algae!1

In this issue of the “Algae is in Fashion” series, we’ll take a close look at textiles—specifically, fabrics derived from alginate. In the next issue, we’ll examine the process and players involved in cellulosic, hydrocolloidal, and lipid-based fabrics!

After that, we’ll take a look at bioplastics for apparel (but not for packaging, which is another animal).

The ecological and economic problem in fashion is well documented, and we included a brief overview in Part 1, so we’ll just jump right into the process and player(s) here.

If you love algae-related cartoons and don’t care for any of the above, you’re still covered! Just scroll to the end 😇. But, if you’re into hearing about the other fiber you need in your diet, read on!

Algae’s “It” Factors

The desire for alternatives to synthetic, petroleum-based fabrics such as nylon is not new. Organic fibers have been proposed using a number of fast-growing terrestrial plants as feedstocks in the past — hemp, bamboo, various pulps, husks, and otherwise discarded biomass.

So what makes algae so apt to the task of creating a commercially viable, organic alternative?

Instead of trotting out the talking points about the benefits of macroalgae cultivation (carbon uptake, local de-acidification, no need for fertilizer or pesticides, “just add sunlight,” fast growth/regeneration, local ecological benefits, [TAKES A BREATH], responsible beach harvesting, economic and social benefits to local fishing communities, potential to empower First Nations communities and create intergenerational/intercultural knowledge transfer, etc.), let’s just talk about the process and properties post-harvest or cultivation that make algae viable for textiles.

What’s the secret sauce?

But before literally get into the weeds, a quick chemistry refresher may be useful. You probably already know this material, but I personally forgot it sometime during the Summer between high school and college (if it can be said I ever knew it).

Alg-chemy

There appear to be a few pathways for producing algae fibers, utilizing differing biopolymers that can be extracted from both macro- and microalgae.

A polymer is just a molecule made up of smaller building block molecules called monomers. DNA is one of the A-list celebrity polymers, built with monomers called nucleotides.

A natural, organic, or biopolymer is produced by living organisms and found in nature. A synthetic polymer was created in a lab, not found in nature, and usually derived from petroleum-based materials. Silk and wool are natural polymers. Nylon and polyester are synthetic polymers.

A polysaccharide is just a polymer that’s made up of sugars.

A carbohydrate, also known as a saccharide, is a sugar molecule. A carbohydrate can be complex (a polysaccharide, like starch) or simple (a monosaccharide, like glucose). All polysaccharides are carbohydrates, but not all carbohydrates are polysaccharides.

A carbohydrate basically contains carbon, hydrogen, and oxygen. So do lipids (fats and oils). But instead of sugars, lipids are built from glycerol and fatty acids. If you’re familiar with starch and oil, you can intuit the structural differences between lipids and carbohydrates.

If you add a nitrogen to the mix, you get a protein molecule. And if you put all three together, you’ve got yourself a stew going! Or at least a good sandwich.

Alginate and cellulose are both natural polymers (polysaccharides) found in macro- and microalgae, respectively. And they will be the names you’ll need to know if you want to get into Club Circularity.

Today, we’re talking about alginate, and all its gooey glory.

Alginate, Ooze and Ahhs

The diversity of algae, micro and macro, is staggering. But when you think of “seaweed” you might be thinking firstly of brown algae (as opposed to red or green). This branch of the algae lineage includes the Macrocystis, or Giant Kelp, that form dense “kelp forests”. The wavy, brownish-green sea plants that wash up on your local beach, those are likely brown algae, too.

Alginate, a salt contained in alginic acid, is a polysaccharide distributed widely in the cell walls of brown algae. In terms of species to choose from as a potential feedstock for alginate, let’s just say there are options — approximately 1,850 different species (see the higher level branches of the family tree below). So at least in theory, there should be no issue with supply.

There are ways to create apparel using seaweed as a raw, untreated material. We’ll examine the artists and designers creating provocative sustainable designs later, but let’s quickly outline the commercial production process.

To go from seaweed to sweater, there are really three processes:

Extraction

Spinning

Weaving

This assumes you already have your seaweed. Charitably we’ll say you’ve successfully coordinated with a harvesting partner to collect beach cast seaweeds or you’ve worked with a farmer to get trimmed biomass off the lines, to the dock, and in your facility, ready to go. So what’s next?

Extraction

There are basically five steps to get the alginate you need from the seaweed, a process called extraction.

Acidification of the seaweeds

Milled seaweed is soaked in a ~2% (weight/volume) formaldehyde solution for several hours, often overnight.

The remaining solid is treated with an acid solution (HCl) for a few hours.

Alkaline extraction with sodium carbonate (Na2CO3)

Next, the solid residue is extracted using a warm sodium carbonate (Na2CO3) solution.

Separation of liquids and solids

Precipitation

Then the liquid portion is precipitated by ethanol (95%+) with a ratio of 1:1 (v/v).

Drying

Finally, the solid output is dried in oven at 50–60 °C. At that point you have a soluble sodium alginate powder.

Several novel techniques are currently being researched, applied, and published for review. If any of these techniques move the needle, the resulting efficiencies could be very valuable to commercial producers. Current investigations include the use of ultrasound to specialized enzymes and microwaves—an interesting space to watch as this market grows (See the Trends in Food Science & Technology paper in the references for more).

But once you have your powdered soluble alginate, the sky’s the limit. Here’s a quick sampling of existing applications:

Texturizing agents (thickening and gelling)

Fat substitutes

Tenderizers for meat

Natural edible coatings

Drug delivery applications

Biomedical tissue engineering

and of course, nanofibers!

So now, with the versatile raw material in hand, it’s time to produce a textile fiber. Or, as I am calling it, employing the Dope-a-Rope strategy.

Spinning (Dope-a-Rope)

The fiber production process is three-fold:

Create the dope: The sodium alginate powder is mixed with water and any other soluble additives, to create a gooey solution, or “dope.”

Spin the dope: The dope solution is processed through a spinnaret or nozzle within a coagulation bath, often filled with a salt solution such as calcium chloride. This process, “wet-spinning,” converts the goey mass into a fiber by linking polymer chains to form fine filaments during extrusion. This is the same process used to produce Rayon.

Wash and dry the dope: The resulting fiber is washed, stretched, and dried before being cut to size for further processing. This process produces raw fiber from which yarn and fabrics can be woven.

Weaving

The final process, turning the raw fiber into yarn or fabric:

Carding – The staple fibers are brushed and aligned into a loose web.

Slivering/Drawing/Roving– The fiber web is condensed into thick, rope-like strands called slivers, which are stretched and blended for consistency. The drawn fiber is further thinned and slightly twisted for strength.

Spinning – The roving is tightly spun into yarn.

Weaving or Knitting – The yarn is interlaced (woven) or looped (knit) to create fabric.

And there you have it! Fairly simple overall to go from seaweed to sweatshirt, no? Just three complex processes consisting of 12 steps, requiring specialized knowledge, facilities, and equipment.

Thankfully, enterprising technologists and entrepreneurs remain undaunted. The processes described above are not only feasible but are also actively being commercialized.

And for those more or less following the process tailored to Alginate, there’s an elephant in the room (and it’s based in North Carolina).

Looming Large

Keel Labs (🇺🇸 US)

Algal Tech 🧪: Fibers & Fabrics

Species / Biopolymer: Brown macroalgae (exact species unconfirmed) / Alginate

Flagship 🏴☠️: Kelsun™

Differentiators 💡:

First movers

When you talk about alginate fashion, there’s really one company to talk about. I reserve the right to update and edit this post after initial publication, but as of 03/01/25, Keel Labs (formerly AlgiKnit — like Alginate!) is miles ahead of the pack with regard to Alginate.

Of course, Alginate is not the only game in town! We’ll see that in terms of commercial scale, Cellulose derivations appear to have the most traction so far, and there are entrants into the market utilizing other hydrocolloidals such as agar and even lipids from microalgae.

Pentagram branding / Effective storytelling

Keel and Kelsum look great. Nobody tells Keel Labs’ story better than Keel Labs. Their visual and social content is informative but not preachy. It’s transparent, sufficiently technical, and comfortable in its own skin.

Storytelling is an integral component of gaining traction, especially in fashion. Unfortunately, nobody ever asked or cared how nylon was made. But now, companies need to explain how their beneficial/circular materials work (chemically and economically) while still being cool. Keel is on track with the formula.

Interoperabilty

Kelsun™ can be blended with cotton or hemp fibers and integrated into existing yarn and textile production systems. This gives the team options. And if, for some reason, they get acquired by an enormous textile conglomerate, it’s an easier sell.

Strategic Partnerships

By working with sustainability icons such as Stella McCartney, vision-aligned retailers such as Outerknown, and savvy design entrepreneurs such as Mr. Bailey, Keel Labs is laying a foundation for growth that’s dissimilar to that of its cellulose competitors. It is not sitting back in the blend. It’s out front, arm-in-arm with collaborators who are creatively engaging with the material in a mutually beneficial way.

Careful with claims

There are some claims about seaweed clothing that don’t have a robust, clear framework of evidence to back them up (benefits for the skin, for example). But certifying biodegradation? Doable and worth celebrating. Touting the benefits of a non-petroleum based, renewable feedstock? Doable and with celebrating.

Keel Labs, in this sense, avoids a trap that some seaweed entrepreneurs fall into by overselling kelp itself. They don’t cite ideal Macrocystis growth rates, or rely on overly rosy broad concepts about seaweed-as-virtue. And what they do highlight as benefits, they back up.

Funders / Accelerators 💰:

Fashion For Good (🇳🇱 Netherlands)

Starlight Ventures (🇺🇸 US)

Third Nature Ventures (🇺🇸 US)

Collaborative Fund (🇺🇸 US)

Horizon Ventures (🇭🇰 Hong Kong)

H&M Ventures (🇸🇪 Sweden)

Notable Partners / Customers 🤝 :

Outerknown, Brand (🇺🇸 US)

Stella McCartney, Designer / Brand (🇬🇧 UK)

Daniel Bailey (aka Mr. Bailey), Product Designer (🇬🇧 UK)

Honorable Mentions / Links

KIMICA Corporation — Industrial Alginate Producer

Sorbalgon® — Calcium-alginate wound dressings

Collaboration to produce a wool-alginate blend:

The Woolmark Company (🇦🇺 Australia)

IMPETUS Group (🇵🇹 Portugal)

Südwolle Group (🇩🇪 Germany)

Runa Ray — Fashion designer and environmentalist using/inspired by treated seaweeds

Seaweedworks: Design collective creative handcrafted luxury seaweed apparel

NORA (Nordic Atlantic Cooperation) Blue Fashion Challenge — High end fashion from Fish Leather, Seaweed, and Sealskin

EU TexMaTer Program: EU funded program sponsoring R&D for the retrieval of novel TEXtile solutions from MArine and TERrestrial biomass. WATCHING THIS SPACE!

Personal Note

Even in the early days of writing this newsletter I’ve had the refreshing experience of learning about innovations and activities that are thriving outside the United States. I tend to speak, either intentionally or not, from the perspective of an American. Although I spent the formative years of my childhood in Canada, I still tend to fall into the same perception trap as many other Americans: I miscalculate the Earth’s center gravity by default.

There’s another positive thing about algae— they don’t care about where you’re from or what language you speak, but they’re incredibly generous if you’re willing to genuinely engage. I’ve noticed this about the people I meet in the algae community as well.✌🏼

References

An overview of the contribution of the textiles sector to climate change [Frontiers in Environmental Science]

Textiles: a viable market for seaweeds? [Phyconomy]

Brown Algae [Freshwater Algae of North America (pp.851-871), Edition: 2nd, Chapter: 19, John D. Wehr]

An Updated Classification of Brown Algae (Ochrophyta, Phaeophyceae) [Cryptogamie Algologie]

Overview of alginate extraction processes: Impact on alginate molecular structure and techno-functional properties [Trends in Food Science & Technology]

Refractometer Application for Wet-Spinning of Sodium Alginate Fibers [Spec Sheet: K-Patents Process Instruments]

The Basics of Fiber Processing [Textile Ranger]

A Brief Review on the Development of Alginate Extraction Process and Its Sustainability [Sustainability]

Methods of extraction, physicochemical properties of alginates and their applications in biomedical field – a review [Open Chemistry]

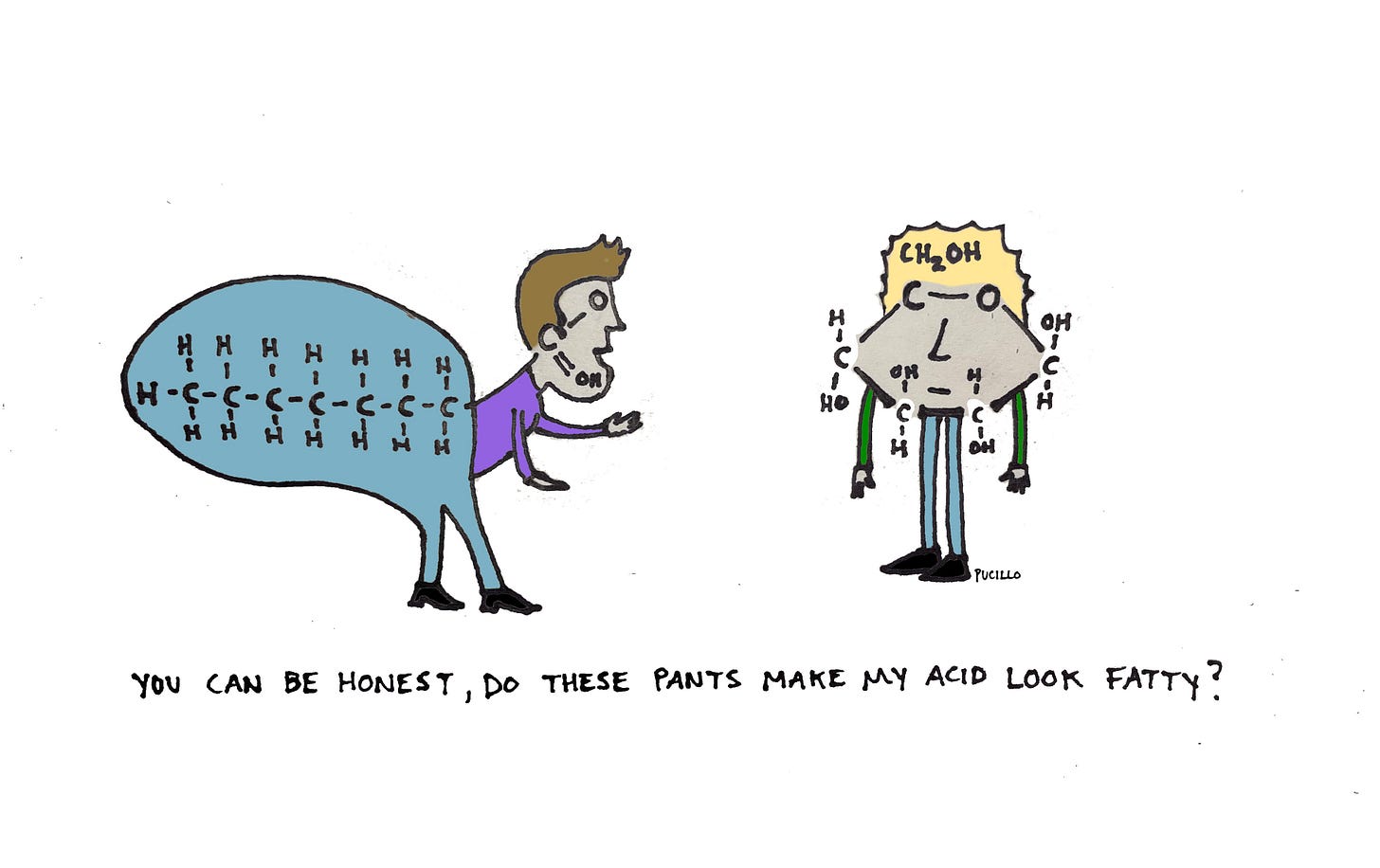

Cartoon

Algae fabric t-shirt idea. You might contend that petro chemicals are also immensely flexible, which is true. But petro chemicals are also algae, just the long dead kind.