Algae is in Fashion: (1) Pigments of the Imagination

Issue #03: The stylish biotech that could literally make our world cooler (Part 1)

From cowboy boots to the clerical collar, fashion trades in symbols as much as materials. What we wear announces our attitudes, allegiances, aesthetics, and aspirations.

So, if the fashion industry has functioned as the costume for capitalism on a macro level,… how do we all look? And what would we rather say?

The results, from an Earthrise perspective, are not flattering. But also, thankfully, not static. We have the ability to shift the system of apparel production to waste and emit less. And while it’s not a silver bullet (a type of solution famously non-existent in the climate space), algae-based materials (micro and macro) can play a pivotal role in that transition.1

Algae-derived materials are biodegradable, non-toxic, and require fewer resources for cultivation and processing. But will they deliver on their promise and scale as needed?

To paraphrase Socrates — the unexamined wardrobe is not worth wearing.

What follows is the first of a series that looks for signals of algae-based innovation in the materials of fashion — the obstacles and opportunities. From hype to hope, we’ll look at algal options for dyes (Part 1), fibers (Part 2), and foams (Part 3). Prince William has also purchased seaweed earrings2, but we won’t go too far into accessories.

There may be tangents, and there’s also a cartoon, but first, there’s a problem 🙄

Too Much, Too “Fast”

The apparel industry is considered one of the most wasteful, carbon-intensive sectors of the global economy. Petrochemical-based dyeing results in staggering C02 emissions, streams of non-biodegradable waste, and exorbitant water usage (which becomes polluted in production).

Here are a few quick facts to set the stage:

The fashion industry is responsible for 10% of humanity’s carbon emissions — More than all international flights and maritime shipping combined.

The equivalent of one garbage truck full of clothes is burned or dumped in a landfill every second.

85% of textiles go into landfills annually (enough to fill the Sydney harbor).

35% of all microplastics come from laundering synthetic textiles like polyester. Washing clothes releases 500,000 tons of non-biodegradable microfibers (~50 billion plastic bottles) into the ocean annually.

Polyester releases 2-3X more carbon emissions than cotton, but it takes about 2,000 gallons of water to produce a pair of cotton jeans. That’s equivalent to 8+ cups of water daily for 10 years.

The fashion industry consumes the most water of any industry apart from agriculture (more than energy, meat, beverage, construction, auto, etc.). It is responsible for 20% of all freshwater pollution (the textile dyeing process).

Of course, there’s more. And the fashion industry is aware of its machinations. It’s just in too deep to stop the presses.3

But if you’re still reading (and not staring pensively at your raw denim collection), let’s look at some of the potential solutions enabled by algal biotech.

Firstly, the dyes and how algae color our world —

Synthetics are so over

Traditional textile dyeing relies on synthetic dyes produced from petroleum-derived chemicals. The primary materials used in making synthetic dyes are coal tar and petroleum. The pretreatment, dyeing, and finishing process require enormous volumes of water and energy, and they generate wastewater laden with toxic compounds (including heavy metals, persistent organic pollutants, and high salinity) that are difficult to treat.

These effluents contribute significantly to water pollution and adversely impact human health and aquatic ecosystems.

There are a few main reasons that synthetic dyes still benefit the fashion industry:

Natural dyes have traditionally cost more to produce, as it’s been laborious to extract colorants from raw materials

Natural dyes have traditionally had low color values and long dyeing times compared to synthetics

Synthetics work best with other synthetics. The system reinforces its own use as natural dyes also work best with natural, not synthetic, fabrics.

Algae is a Natural

When we admire the flamboyant pink plumage of a flamingo (or the lawn ornaments they’ve inspired), we probably don’t think about Haematococcus pluvialis, Chlorella zofingiensis, Chlorococcum, or Phaffia rhodozyma — and we’d be forgiven.

But these algae (among many others) have already been coloring our world in surprising ways.

Take the pink of the flamingo. Flamingos, like salmon, eat small fish and crustaceans, which eat zooplankton, which feed on algae like H. pluvialis. This algae (and the others listed above) contains Astaxanthin, a powerful antioxidant and reddish carotenoid pigment produced by the algae noted above. The bio-accumulated pigment gets distributed through the feathers, beaks, and legs. Et voilà!

Without H. pluvialis and Astaxanthin, the flamingo (and your Salmon dinner) would be white or grey — and John Water’s cult classic may have been a bird of another color.4

Pick a Color, Any Color

In the race from the food chain to the supply chain, there are a number of also-rans—or, more accurately, never-rans.

Bio-based dyes have often been associated with whole-organism, bespoke processes with no realistic potential to scale to modern needs in a responsible way. Petrochemical dyeing processes benefitted from the Industrial Revolution R&D that lifted all boats (while entrenching deeply problematic production methods).

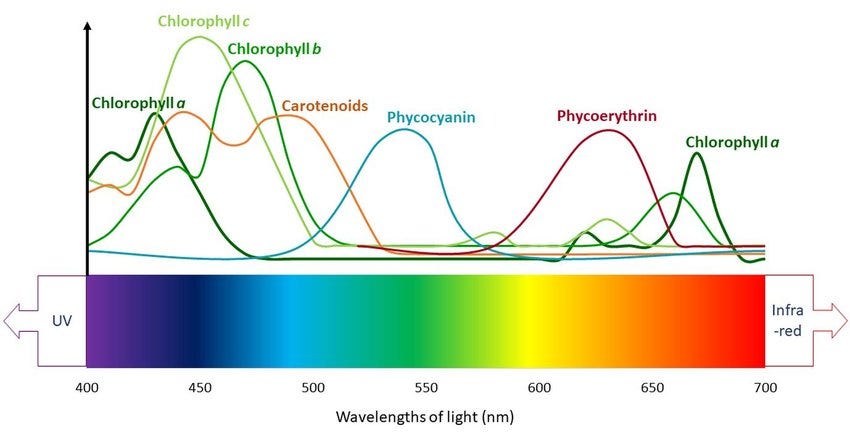

What makes algae different — and its evolutionary ace-in-the-hole, is its diversity. Apart from the familiar blue/green Chlorophylls and reddish Carotenoids highlighted above, algae provide a wide range of color options along the visible light spectrum. This variability, a function of algae’s broad molecular diversity, is a significant advantage of algal-based dyes.

Not only are the color choices strong, but the colors themselves are strong. Algae-based dyes have been scientifically and commercially proven not to quickly wash out, resist degradation under UV rays (in other words, they are “lightfast”), and adhere well to many different fibers.

Petrochemical synthetics were cheap and ready when the supply chain needed them. However, the real cost is catching up with us.

From Lab to Fab

Here’s how the process of producing algal dye works (basically—I am not a scientist): This assumes cultivated biomass as the feedstock, not existing biomass waste. Each part of the process is a fascinating lever for efficiency and innovation, worthy of a separate investigation.

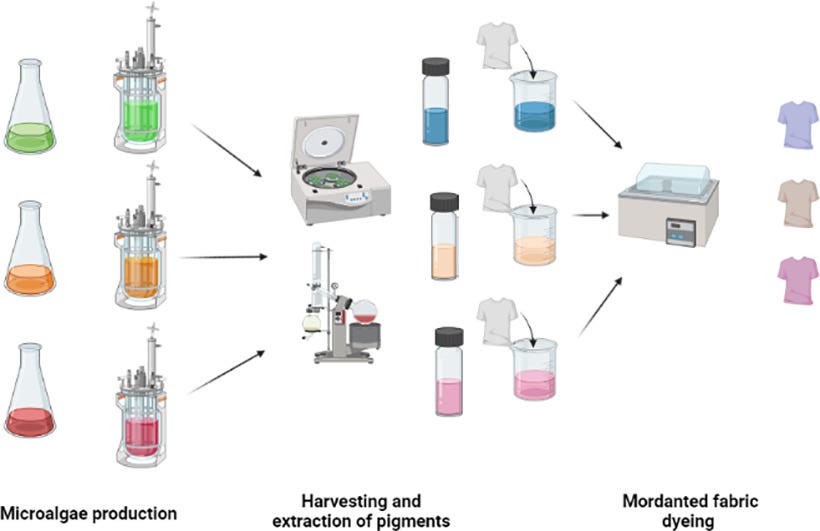

Microalgae Production: Getting the biomass

Growing algae biomass with minimal resource input yields the desired pigments. In theory, the method of producing microalgae could vary from controlled indoor bioreactors to large outdoor raceway ponds.

Pigment Extraction: Getting the active ingredient

Using mild, eco-friendly solvents (acetone, for example) to isolate pigments without generating toxic byproducts.

Application: Binding the dye to the textile

The extracted pigments can be integrated into dyeing processes that require less water and energy while producing a carbon-negative output.

Application often occurs with the help of bio-mordant (a non-toxic chemical that helps dyes adhere to fabrics). Examples include aloe vera, citric acid, onion skin, and turmeric.

Traditional mordants (unfortunately) work well as binding agents, but they can be quite toxic and contribute to the pollutive process (tannic acid, chrome, copper, and metal salts, for example).

The Cool Kids 🌍

So, which companies are out there building the future algal dyes?

Amidst what seems to be a flurry of R&D and academic validation, these six (6) companies appear poised to take the lead.

1. Living Ink Technologies (🇺🇸 US)

Algal tech 🧪 : Dyes (Textile & Packaging)

🏴☠️ Flagship(s) 🏴☠️: ALGAE BLACK™ and ALGAE INK™

Differentiator 💡:

A clear focus on replacing fossil-fueled carbon black by repurposing discarded algae biomass, allowing for applications in textiles/apparel, packaging, and cosmetics.

By focusing on waste valorization, Living Ink utilizes algae as a renewable pigment source and almost doubles its contribution to the circular economy.

Living Ink’s product can be used in various other markets, such as cosmetics and paint.

Funders / Accelerators 💰:

Notable Partners / Customers 🤝 :

Nike (& Billie Eilish), Packaging & Apparel, (🇺🇸 US)

Vollebak, Apparel, (🇬🇧 UK)

Sway, Packaging, (🇺🇸 US)

2. Algaeing (🇮🇱 Israel)

Algal tech 🧪 : Dyes (Textile)

🏴☠️ Flagship(s) 🏴☠️: Algadye™ and Algaink™

Differentiator 💡:

Algadye™ is designed for large surfaces. Algaink™ is an advanced versatility ink that adapts to all fabrics and materials.

Their approach emphasizes the cultivation and the effective use of algae waste, positioning their products to easily adapt within conventional manufacturing systems.

Compared to traditional processes, this process uses 80% less water and reduces 70-74% of GHG emissions.

Funders / Accelerators 💰:

Closed Loop Partners (🇺🇸 US)

Winner, H&M Foundation Global Change Award (2018)

Notable Partners / Customers 🤝 :

Beti, Textile Manufacturer (🇸🇮 Slovenia)

3. Mounid (🇸🇪 Sweden)

Algal tech 🧪 : Dyes (Textile)

Flagship 🏴☠️: ALGID® Blue Algae Ink

Differentiator 💡:

Mounid’s technology is engineered to reduce water and energy usage by up to 90% while maintaining compatibility with existing dyeing machinery.

Funders / Accelerators 💰:

Vinnova (🇸🇪 Sweden)

Wargön Innovation (🇸🇪 Sweden)

Chalmers Industriteknik (🇸🇪 Sweden)

Industridoktorn (🇸🇪 Sweden)

Notable Customers / Brand Partners 🤝 :

Fristads, Apparel, (🇸🇪 Sweden)

4. Zeefier (🇳🇱 Netherlands)

Algal tech 🧪 : Dyes (Textile)

Flagship 🏴☠️: TBD (R&D / Commercialization stage)

Differentiator 💡:

Similar to Living Ink, Zeefier uses seaweed residues to produce its textile dyes. It collects from local/regional partners and beaches, so there is no direct cultivation, and it is a great circularity partner.

A major boost is their recent participation in the AlgaeVALOR

Their color palette is also a differentiator — softer, more yellow tones as opposed to the more commercial-ready blues and blacks.

Funders / Accelerators 💰:

Interreg (🇪🇺 EU)

Blue Bio Value (🇵🇹 Portugal)

Notable Customers / Brand Partners 🤝 :

AlgaVALOR Project, Project / Consortium (🇪🇺 EU)

North Sea Farmers, Macroalgae Cultivation (🇳🇱 Netherlands)

The Seaweed Company, Macroalgae Cultivation (🇮🇪 Ireland)

Algaia, Microalgae Cultivation/ Bio-refinement (🇫🇷 France)

Spaak, Consultant (Circular Economy) (🇳🇱 Netherlands)

UGent, University / Research (🇳🇱 Netherlands)

The Knitwit Stable, Wool Producer (🇳🇿 New Zealand)

5. Oceanium (🏴 Scotland)

Algal tech 🧪 : Dyes (Packaging & Textile)

Flagship 🏴☠️: OCEAN INK®

Differentiator 💡:

A product offering from a well-capitalized company with a track record of producing other algae-derived nutra/pharmaceutical and pet food products

Versatile applications for luxury textiles, printing, and packaging, however currently only offered in gold and black. Oceanium is actively testing on a range of fabrics, so it will be interesting to see what’s next there.

(Notable) Funders / Accelerators 💰:

Builders Vision (🇺🇸 US)

Katapult Ocean (🇳🇴 Norway)

Sky Ocean Ventures (🇬🇧 UK)

Sea Ahead (🇺🇸 US)

Notable Customers / Brand Partners 🤝 :

TBD for textile applications

6. Sea Dyes (🏴 Scotland)

Algal tech 🧪 : Dyes (Textile)

Flagship 🏴☠️: TBD (R&D / Commercialization stage)

Differentiator 💡:

Sea Dyes is still in the R&D / pilot stage, so they have not published much information about their products.

However, they are developing an interesting palette. They are currently using shades of purple, magenta, red, and brown, with more to come.

Funders / Accelerators 💰: TBD / Not Public

Notable Customers / Brand Partners 🤝 :

Crubag, Designer/Retailer (Apparel), (🏴 Scotland)

Planet Approved

Algae can be cultivated sustainably using minimal resources and produce zero waste during processing.

Replacing synthetic dyes in petrochemicals and tar would be a welcome step toward slowing (and ultimately stopping) fossil fuel extraction.

Algae also absorb carbon dioxide during photosynthesis, which aids in carbon sequestration. Thus, they are an integral part of a circular economy approach in the textile industry.

The market forecasts seem to align as well.

The global textile dyes market is expected to reach USD 18.21B by 2033, up from $12.42B in 2024 and growing at a CAGR of 4.9%. The global market for microalgae-based products is expected to reach USD 23B by 2030, up from $13.25B in 2023 — a CAGR of 8.2%.

Despite the rosy estimates, I wonder if the market analysts who compile these reports properly account for all the industries where algae have feasible market penetration 🤔.

Is it Ready to Wear?

The grain(s) of salt 🧂… With any new technology that’s advancing against an entrenched system, there are going to be hurdles:

The technology must still proceed under the faster/better/cheaper rubric. One of the most helpful aspects of potential adoption seems to be that much of the industry's infrastructure can remain intact. This integration allows for a feedstock plug-and-play, reducing friction for manufacturers, brands, and consumers.

Additional research is needed to define the most efficient extraction methods and improve commercial viability.

Large-scale biomass production (or the large-scale management of biomass waste) is still a logistical puzzle.

Regulatory complexities and uncertainties. These could include stalled funding grants, preferential conditions tailored to existing petrochemical methods, or simply a lack of speed needed to permit facilities that would enable the integration of algae into the fashion supply chain.

Despite the hurdles, it’s awfully exciting to consider the potential (imminent 🤞) impacts. And a hearty salute to the teams already doing the good work! 🫡

For Another Day

Seaweed based natural fibers (👕)

Algal-based bioplastics and foams (🥽)

Algal pigments for cosmetics (💄)

Algal pigments for food coloring (🍭)

The use of algae to treat textile wastewater polluted during traditional dyeing (🚰).

Articles & Papers

A No-Hype List of Seaweed and Algae Innovations in Fashion [Ecocult]

Developing Natural Pigments from Microalgae [Algae Planet]

Microalgae pigments as a sustainable approach to textile dyeing: A critical review [Algal Research]

Extraction of algal pigments and their suitability as natural dyes [Journal of Algal Biomass Utilization]

Potential environmental and health risks of textile dyes and mechanisms treatment for Environmental safety by algae-based technologies: A review [Mesopotamia Environmental Journal]

Algae-based Dyes for the Textile Industry [Eurasia Symposium]

Harnessing natural colorants from algal species for fabric dyeing: a sustainable eco-friendly approach for textile processing [Journal of Applied Phycology]

Using chlorella vulgaris as a natural-textile dye [Environmental Research and Technology]

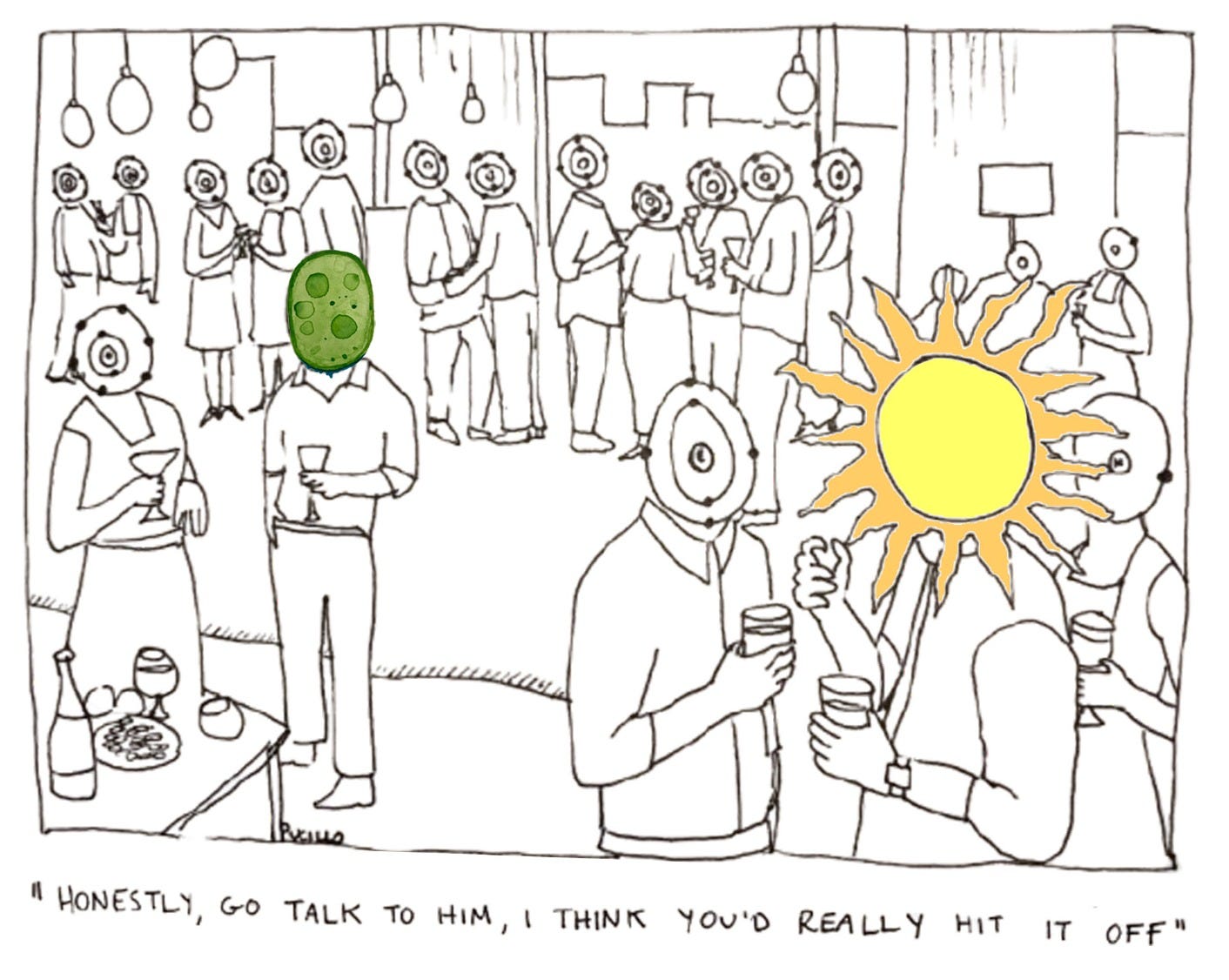

Cartoon

Spoiler: The Blob will always, somehow, tie it back to algae 🙃

The quote from Zoolander comes to mind (replace “Mugatu” with “Seaweed,” and it’s oddly near accurate): “Mugatu is so hot right now he could take a crap, wrap it in tinfoil, put a couple fish hooks on it and sell it to Queen Elizabeth as earrings.” — Maury Ballstein

For positive markers of change across the fashion industry, the following orgs and initiatives are encouraging:

Apparel Impact Institute (and the Fashion Climate Fund )

The same goes for corals via the symbiotic arrangement with Zooxanthellae. Without algae, corals will bleach and cannot survive.

This is awesome! Thanks for the great info!